Decorated

Innovated

Captivated

Anticipated

Accelerated

Protected

Trusted

Cultivated

When It Needs To Be

Customer Success

Georgia-Pacific is a single, integrated source for all your corrugated packaging needs, focused on making your success a priority. We provide innovative corrugated boxes, bulk bins, display-ready containers, and sustainable packaging solutions for a variety of customers in diverse markets. We proudly serve the needs of many industries, including:

Beer / Wine / Spirits

E-Commerce

Produce

Plastics, Chemicals & Rubbers

Consumer Product Goods

Industrial Goods

Food & Beverage

Club Channel

Our dedicated team of packaging experts is ready to help you improve your total supply chain.

Check out some of our customer success stories below.

Produce

Case Study: Gerawan Farming

Georgia-Pacific’s Dedication to Quality Protects One of the Top Fruit Farm Brands in the United States

Challenge

Maintaining the highest standards is critical to becoming one of the nation’s largest growers of peaches, plums and nectarines. California’s family-owned Gerawan Farming has gained a well- earned reputation for fruit quality and packaging integrity.

Both the fresh fruit and its packaging must undergo challenging conditions en route from farm to marketplace. After enduring high humidity cold storage conditions, the boxes must then serve as display cases for retailers and large buyers. For those reasons, this family-owned farming company needed a supplier that could produce top quality boxes to match the brand’s dedication to quality, providing both structural integrity and visual appeal.

Solution

Georgia-Pacific’s Madera facility provided Gerawan with an overprint varnish to protect and enhance their Prima brand. This successful solution allowed Georgia-Pacific to transition Gerawan’s boxes to its bliss style packaging — a sturdy corrugated solution that features a unique composition which improves package strength and appearance.

To further communicate quality through the brand’s packaging, Georgia-Pacific introduced a high- performance white linerboard for both the inside and outside of Gerawan’s boxes. This bright white paper liner offers superior wet-strength properties, ideal for the fruit’s high humidity cold storage conditions.

Result

Georgia-Pacific’s service-oriented team and high quality solutions have allowed Gerawan to grow along with its volume and product line. Results include:

- Improved appearance of packaging, protecting Gerawan’s high-quality brand image

- Enhanced package strength to withstand high humidity cold storage conditions

- Improved stackability, from one to two pallets high

Case Study: Savco Worldwide

Georgia-Pacific Helps Smaller Player, Savco, Compete Against Big Producers

Consumer

Products

Case Study: Smooth Sailing

How Georgia-Pacific’s Innovative Packaging Paved the Way for a 40 percent Increase in Sales for Pirate Brands

Challenge

It’s always nice when someone else knows what you need before you even have to ask. Pirate Brands, located in Sea Cliff, N.Y., is famous for its healthy and fun snack food products, including Pirate’s Booty®, Original Tings® and Smart Puffs®. Founded in 1987, the company has grown tremendously and its products are now sold throughout the country in convenience stores and in larger grocery chains, such as Wal-Mart, Super Mart and BJ’s.

Georgia-Pacific has enjoyed a long-time relationship with Pirate Brands, providing retail ready shipping cases for its well-known brands. GP proactively showed the company how a revamped retail ready package with new features would strengthen shelf presence and increase demand for its products.

Solution

The new Pirate’s Booty secondary packaging features colorful graphics that coordinate with the primary packaging for brand consistency and stronger shelf recognition.

Georgia-Pacific’s new design included its innovative Clean and Easy-Perf® technology.

The new design:

- Consistently creates a smooth perforated edge to enhance brand image

- Expedites stocking the product on store shelves, allowing retailers to save on labor costs

- Eliminates the need for a knife to open the carton, making it a safer solution for retail stock employees and eliminates a source of product damage.

Result

Thanks in part to the state-of-the-art package stemming from a trusted relationship, Pirate Brands has experienced a 40 percent increase in sales. Because of the initial success, the company has since incorporated Georgia-Pacific’s Clean and Easy-Perf® technology for all of its brands

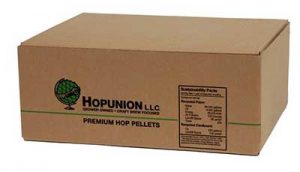

Case Study: Cheers to Store Packaging

How Georgia-Pacific Generated Valuable Storage Savings for a Brewery Supplier

Challenge

Hopunion, LLC is renowned in the craft beer industry for producing premium hops, a flower used as a flavoring agent in beer. The company’s cold-storage boxes hold 44 pounds of this heavy herb. When stacked more than two pallets high, the 31-pound corrugated medium container being used by Hopunion would collapse, crushing the product. In addition, the box had a small print area that dwarfed the company logo and graphics, and was cluttered with product information.

With plans to increase its production by 46 percent in 2012, Hopunion turned to Georgia-Pacific to develop a box with enhanced stacking strength that would allow the company to save on storage space and showcase its brand with eye-catching graphics.

Solution

GP visited the plant to collaborate with Hopunion and develop a solution to their packaging challenges. GP made the following modifications:

- Reoriented the flute direction to strengthen the box

- Upgraded to a 41-pound corrugated medium to strengthen the package against compression

- Developed a corrugated insert for internal structural support

- Updated graphics and expanded print area to improve placement of sustainability and product information, and provided a cleaner design on the box surface

Result

With GP’s modifications, the boxes can now be stacked four pallets high. As a result, Hopunion saved more than $50,000 by decreasing warehouse storage and shipping costs within the first year alone.

In addition, the company’s logo now appears bigger and bolder on the box, alerting craft brewers to the Hopunion brand.

Hopunion was so satisfied with the value that GP added that it now purchases 100 percent of its packaging from GP. In addition, Hopunion has recommended GP to other manufacturers in the craft brew industry.

Case Study: Tea Time

How Georgia-Pacific Helped Milo’s Tea Expand Their Market Share

Challenge

Milo’s Tea is famous in the south for their authentic and original sweet tea. As word spread and demand from both consumers and retailers increased over the years, the company needed to expand their distribution reach. To do this, the company would have to replace its reusable plastic crates with a more efficient solution.

The plastic crates presented limitations for a growing company like Milo’s because they had to be returned to their production facility and washed after every shipment, leading to increased transportation costs and a limited area of distribution.

Solution

Georgia-Pacific collaborated with Milo’s Tea to identify a solution that would expand Milo’s distribution reach to a level not possible with Milo’s current process, without increasing costs and reducing subsequent retail margins.

Utilization of GP’s Packaging System Optimization (PSO®) process resulted in implementation of a corrugated bliss container. Once assembled, the package could be used in Milo’s current line or adapted to fit growing lines, as the company expanded. The new solution allowed Milo’s to move to a recyclable one-way shipper, removing the restrictions and costs associated with the plastic crates.

Result

Since incorporating Georgia-Pacific’s corrugated bliss containers, Milo’s has achieved:

- The ability to simultaneously service an expanded territory while reducing costs and providing consumer value by lowering retail pricing.

- An increase in market share through expansion of their distribution market into thousands of retail stores now serviced by Milo’s Tea providing product directly to retail warehouses instead of through route deliveries to individual stores.

Industrial

Goods

Case Study: Under Pressure

How Georgia-Pacific’s Quality Inspection Improved Box Integrity for a Plastics Compounder

Challenge

Plastics compounders serve a variety of industries, such as automotive parts and household appliances. One such company ships 750-kilogram pallets of its product from its plant in 48” x 45” x 39.5” octagonal boxes.

However, the company was facing serious quality control issues with its packaging. The glue joints on its boxes were popping frequently, causing structural failure. Many of the boxes wouldn’t make it from storage to transit, forcing employees to repack products in the warehouse, resulting in added expense and labor.

Solution

The plastics compounder called on Georgia-Pacific, who immediately invited the company to visit its Akron, Ohio, facility, which specializes in bulk packaging solutions. While there, the company saw first-hand the level of quality inspection missing from its previous supplier.

- To remedy the structural issues of the containers, Georgia-Pacific experts made the following changes:

- Inspected one box out of every 20 produced for defects, including a full assessment of all glue joints.

Performed compression and destructive tests on sample boxes, focusing on glue-joint failure and delamination concerns.

Based on its testing, Georgia-Pacific determined that insufficient operator attention to detail was the likely cause of the company’s troubles.

Result

The plastics company switched to Georgia-Pacific for its bulk containers and hasn’t looked back. The company’s shipping boxes are now strong enough to hold valuable cargo without collapsing. As a result, it no longer has the headache of repacking products, which saved time and improved efficiency. In addition, Georgia-Pacific’s responsive customer service ensures that boxes arrive within a day’s notice, reducing the need for forecasting and additional floor space for storage.

Want to find out more?

At GP Corrugated, your questions, comments, and suggestions are appreciated. Please complete the fields below, and a member of our team will contact you shortly.